About Yoshimura Camshafts

The history of Yoshimura

began with high camshafts.

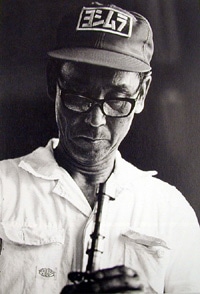

My father, Pop Yoshimura, was one stubborn man.

A man hard to please, yet everyone around him loved him very much as if he was their own father. To me, Pop Yoshimura was both a strict father and a charismatic figure.

He was always surrounded by people. There was always someone visiting our house and talking for hours with him. Besides being a world-famous engine tuner, my father was a very sympathetic person.

Our victory at the Suzuka 18 Hour Endurance Race in 1964 completely changed how I looked at him. I was a junior-high student at the time and was very much into motorsport magazines, through which I learned how difficult it is to win this race. I couldn’t believe that my own father had made the history by winning it. That made me respect him even more.

Within a matter of years, I was unexpectedly told to work on camshafts. Just as we were starting to get really busy tuning the Honda S-series sports cars, my father suddenly became bedridden, probably from overwork, so someone had to replace him. And of all people, he chose me to do the final finish on the camshafts for a twin-cam Honda S800 race car.

It was no big deal really –––– just some polishing with grinding stones –––– but I at the time felt resentment against him for choosing me. Sure, I had for some time been fooling around with some engines on my spare time as a hobby, but I had never done such a proper job before. I refused it, but after getting scolded by my father, I accomplished the task by following his instructions and by coping with mental pressure.

I forgot the exact result of the race, but I remember the Yoshimura-tuned S800 was one of the top finishers. I felt relieved. The race result to me was like an approval of my polishing skills. While the camshafts were mostly done by my father, I was overwhelmed with a sense of confidence.

My father was very proud of the tuned Honda CB750 he built in 1970, which was claimed to hit over 200 kph by the end of a 1 km run, so we took the bike over to the United States to race the AMA road racing series.

After my father and colleagues went back to Japan with positive results, I remained alone in the States for around 5 years absorbing hands-on skills and knowledge in the field of tuning, through diverse experiences which I couldn’t have had if I had stayed in Japan with my father. I was also inspired by so many different approaches of doing things in the U.S..

Every time I saw what Pop Yoshimura was doing, I was thoroughly impressed by his creativity and expertise. Based on the data collected from my close observations and analysis, I started to digitize his production process and finally succeeded to establish the parametric design of camshaft in the late 1970s. Subsequently, however, the calculation became complicated as more and more factors became involved.

Then I found out about a programmable handheld computer which just came out. I jumped at it. I picked one up at an electronics shop, but there was a problem. I didn’t know how to use it and had nobody to teach me. The only support I had was the User’s Manual which was hefty and filled with annoyingly incomprehensible strings of digits and technical jargons. It was quite a challenge, but after some studying of the manual, I was able to make use of the computer, and the designing then became much easier.

My concerns were different from my father’s. One day I eagerly showed him a computer-designed camshaft for Suzuki GS, but his pride as a craftsman refused to accept anything related to computer. He must have known all too well that the fabrication of delicate cam profile requires brilliant craftsmanship as well as subtle sensitivity and cannot be done instantaneously. In his eyes, my computer was perhaps nothing but a nonsense piece of calculating electronics.

Still, he too must have realized that the times have changed. An engineer can no longer single-handedly keep pace with technological developments as motorcycles were evolving quicker than ever. Although he never accepted the computer-designed camshaft in his life, he seemed to have recognized the necessity to go forward. As a matter of fact, by that time in the motorcycle racing scene, works teams were reducing the private teams’ chance of winning by building monster bikes from literally the ground up with the support of ever-increasing funds.

Yoshimura hasn’t changed its finishing process for camshafts. We still polish them with grinding stones in the exact same way as my father taught us. This process will never change, no matter how technology advances.

Yoshimura hasn’t changed its finishing process for camshafts. We still polish them with grinding stones in the exact same way as my father taught us. This process will never change, no matter how technology advances.

Camshafts are still not so profitable as a business, considering the amount of time and effort to design and produce them. Camshaft installation also requires skill and experience. We need to carefully select our retailers since they may have to disassemble cylinder heads to install not only camshafts, but also other related engine components. So why bother with it? Because it significantly improves the engine performance.

The performance of camshaft is one of the most important factors that decide race results. Both my father and I had learned it through countless lessons over the years.

A perfect camshaft delivers amazing results.

Fujio Yoshimura

Camshaft Index